Introduction – Inkless Printing Technology

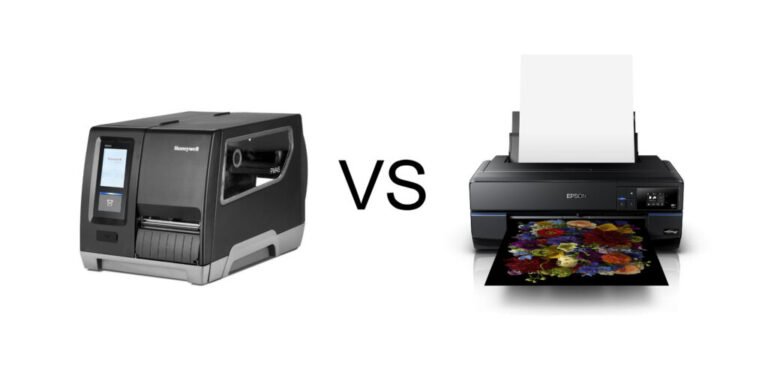

The decision of a printer is often viewed as a one-time purchase that seems like a minor matter. The majority of individuals examine the cost of the machine and end there. However, this approach can turn out to be a costly mistake over several years. This is especially true when considering new technologies like Inkless printing technology. We also conducted an experiment over an extended period to explore how this innovative technology can save both time and money in the long run. We contrasted traditional ink-based systems with new thermal paper roll systems. The findings indicated that the initial cost of hardware is usually a distraction.

Explainable with the Mechanics of Ink Systems

These cartridges have complicated chemical formulas that dry fast on paper. But there are a number of maintenance requirements that are associated with liquid ink. Each time you switch on the machine, it goes through a cleaning process. The users are usually forced to change cartridges, although they may not have had much printing. This dead weight in your overall operating budget is this wasted material.

Comparing the Costs: Ink-Based Printing vs. Thermal Paper Printing

| Category |

Ink-Based Printer |

Thermal Printer |

| Initial Hardware Cost |

Higher (due to the ink cartridge system) |

Lower (simple design) |

| Cartridge/Ink Cost |

Ongoing costs for ink cartridges |

No ink costs (uses thermal paper) |

| Maintenance Costs |

High (due to cartridge replacement and cleaning) |

Low (minimal moving parts) |

| Energy Usage |

High (due to motor and heating system) |

Low (minimal power usage) |

| Inventory Management |

Requires controlled storage for ink |

Simple storage of paper rolls |

| Print Speed |

Slower (ink drying time) |

Faster (instant print) |

| Environmental Impact |

Waste from cartridges |

Less waste (no plastic cartridges) |

| Reliability (Long-Term) |

Prone to print head failure |

Highly reliable with fewer parts |

The Thermal Paper Technology is not that complicated

The physical principle of thermal printing is totally different. It is done using heat-sensitive paper instead of liquid pigments or toners. The thermal printer roll is touched with a printed head that is heated to produce images. The number of moving parts of the machine is very minimal compared to traditional printers. This simplicity minimizes the possibility of mechanical failure when dealing with high-volume jobs. All you have to do is stock a constant amount of Thermal Paper Rolls.

Monitoring the Unnoticed Maintenance Costs

The area of traditional ink systems’ failure is maintenance. When you are not using the print head on a day-to-day basis, the print head may dry out. It is occasionally costlier to replace a broken print head than it is to buy another machine. However, with Inkless printing technology, these maintenance issues are virtually eliminated. Thermal units, such as those using this technology, do not have liquid components, so they don’t face the same problems. The long-term reliability of a thermal printer roll system, powered by inkless technology, saves hours of troubleshooting. This increased reliability can easily translate to a boost in your daily productivity.

The Nightmare of Inventory Management

To store ink cartridges, a climate-controlled place is necessary in order to keep them dry. When you have excess stock, you will have the risk of losing money spent on expired goods. Thermal Paper Rolls are far simpler to handle within a warehouse or office. When kept in places that are not in direct contact with the heat sources, they last a long time. They can be purchased in large quantities without fear of chemical degradation.

Energy Usage and Environmental Effect

The conventional printers also consume a lot of power to move the heavy cartridges back and forth. They would also employ heat to fix the ink or fuse toner to the page. Thermal printers consume less energy because they are usually compact. All used ink cartridges find their way into the trash heaps unless they are recycled. Through Thermal Paper Rolls, there is no need to commit to sophisticated plastic housing units.

There will be speed and efficiency in high-volume situations

One of the inkless printing costs that most business owners do not take into consideration is time. The inkjet printers can be very slow since the page has to dry before it can be handled. When you quickly pick up a page, it will be smeared and destroy the sheet of paper. The thermal printing process is almost instantaneous, and the dry image is instant. The speed of production lowers the cost of labor for waiting for a machine. A conversion to a thermal printer roll would save tens of hours annually.

Computing the Ultimate Cost per Page

In summing the numbers, the inkless printing was far less expensive. The main reason is that with each purchase, you are literally buying plastic housing and branding. The medium and the ink are also integrated into a single product, which is a thermal paper roll. This integration eliminates the middleman and reduces the cost of all transactions. The switch to thermal technology is an obvious victory for the cost-saving leaders, especially when integrated with Inkless printing technology, which further reduces expenses by eliminating the need for ink cartridges and maintenance costs.

Follow us on Facebook for more details.

FAQs

Thermal paper never runs out of ink, does it?

No, since thermal paper never uses any liquid ink. The paper itself is made to change colour by applying specific heat to the surface by the printer.

What is the duration of a thermal printer roll?

The roll length will depend on the diameter that you select in your machine. Even most standard rolls are capable of printing hundreds of individual receipts before replacement.

Is it possible to use thermal technology to print colours?

The majority of the standard thermal printers support printing black letters only and plain monochrome images. Two-color printing is done on specialized paper, but this is not a widespread need.

Are the paper rolls stored under heat conditions?

Yes, you need to keep your paper in a dry and cool place. The paper darkens even before you put it into use due to the high temperatures.

Is the price of the inkless printing that much lower?

Yes, as you are doing away with the most costly recurring element of the system. You just pay for the paper, but not the paper and cartridge.